crystal growing furnace insulation

crystal growing furnace insulation Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- huangpu

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 30days Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Western Europe, Central America, Asia, Eastern Europe, North America

- Certifications

- sGS

About crystal growing furnace insulation

Carbon fiber composite rigid felt and application

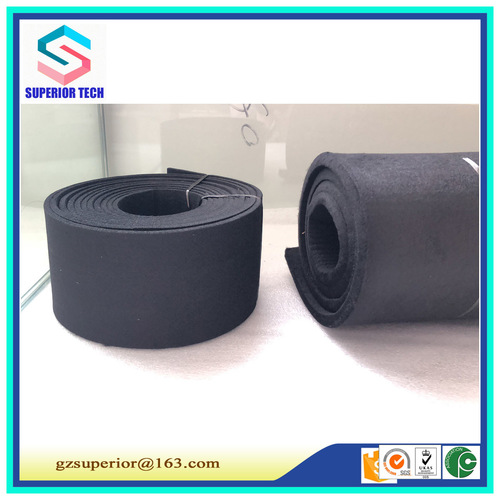

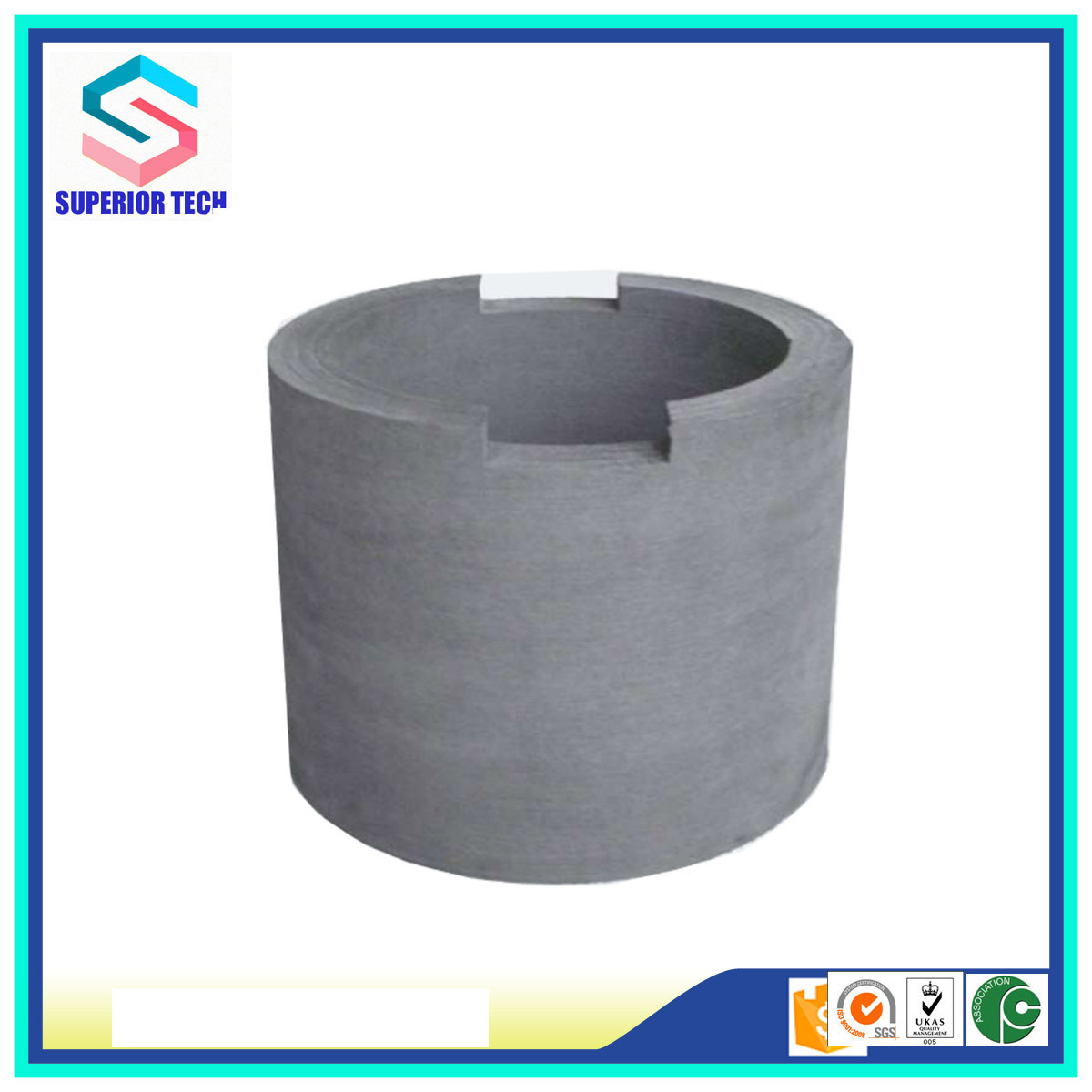

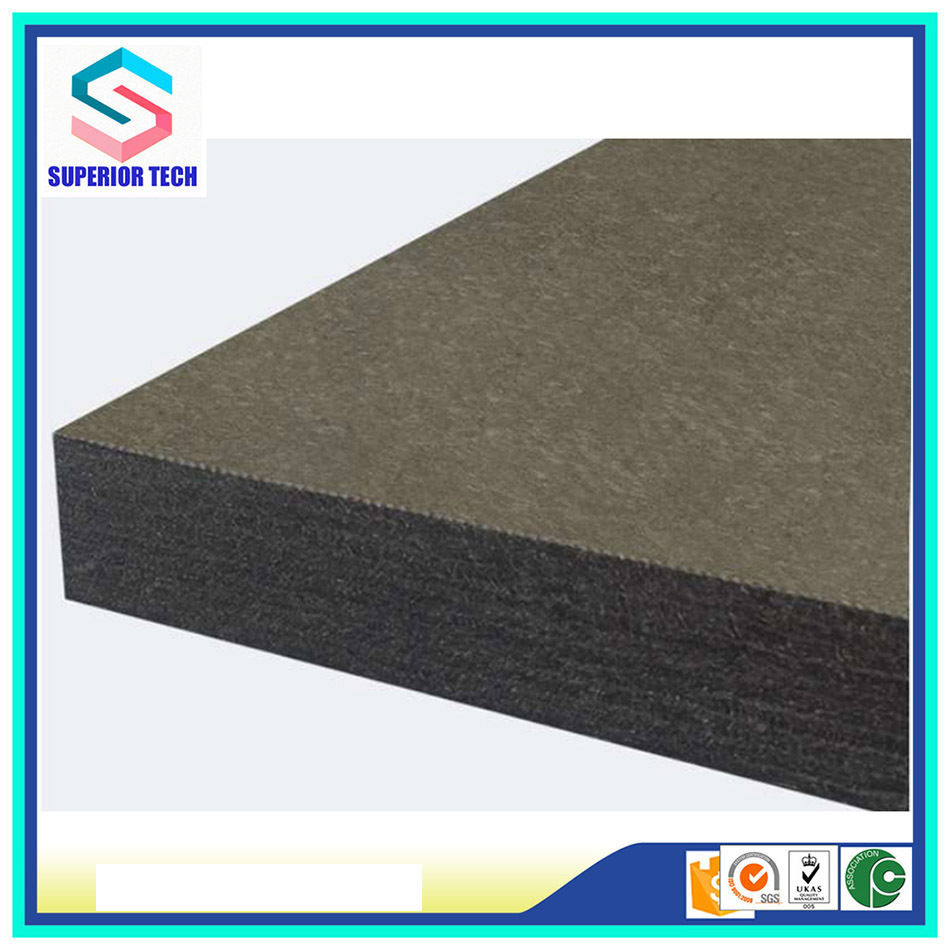

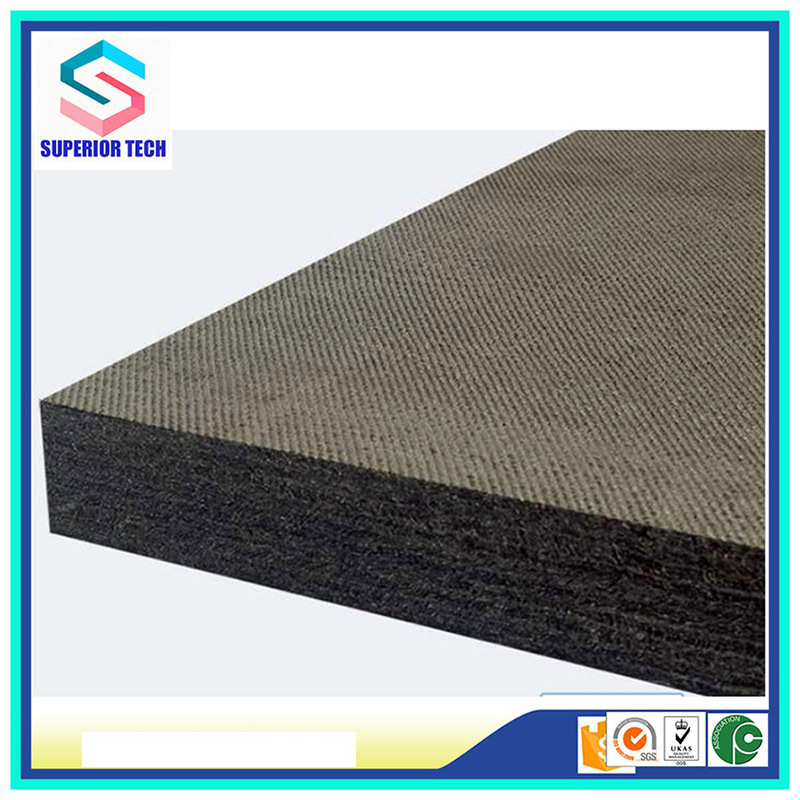

The use of foreign high-quality polacrylonitrile-based raw silk, made by carbon felt matting technology into a carbon felt, and use a small amount of binder to produce the desired product shape after curing, and through a 2400 degrees high temperature graphite forming. The hard felt adopts the density gradient structure technology, and performs various surface processing or purification processes to ensure that the material has the best thermal insulation performance and better oxidation resistance at the high temperature stage, helping the customer to reduce energy consumption and reduce costs.

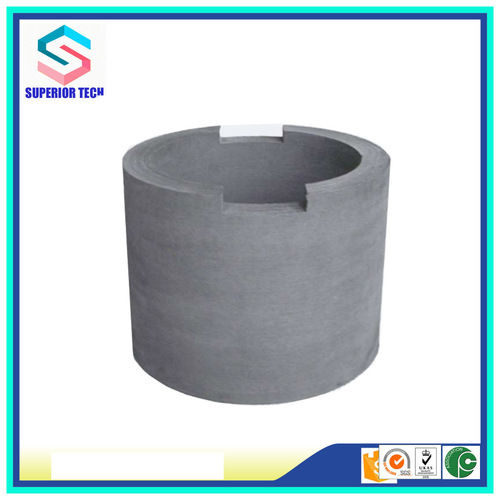

Flat plates are used in high temperature vacuum sintering furnaces and inert gas protection furnaces such as monocrystalline silicon, polycrystalline silicon crystal growth furnaces, quartz furnaces, vacuum furnaces, induction furnaces, high frequency furnaces and heat balance reactors, heat treatment furnaces, carbide production, sintering furnaces , Welding furnaces, high pressure furnaces and other high-temperature furnace insulation materials.

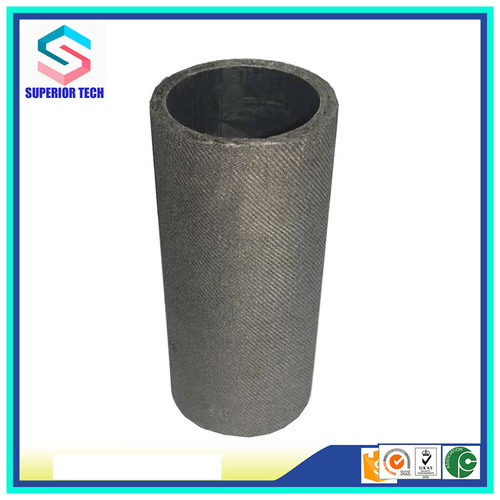

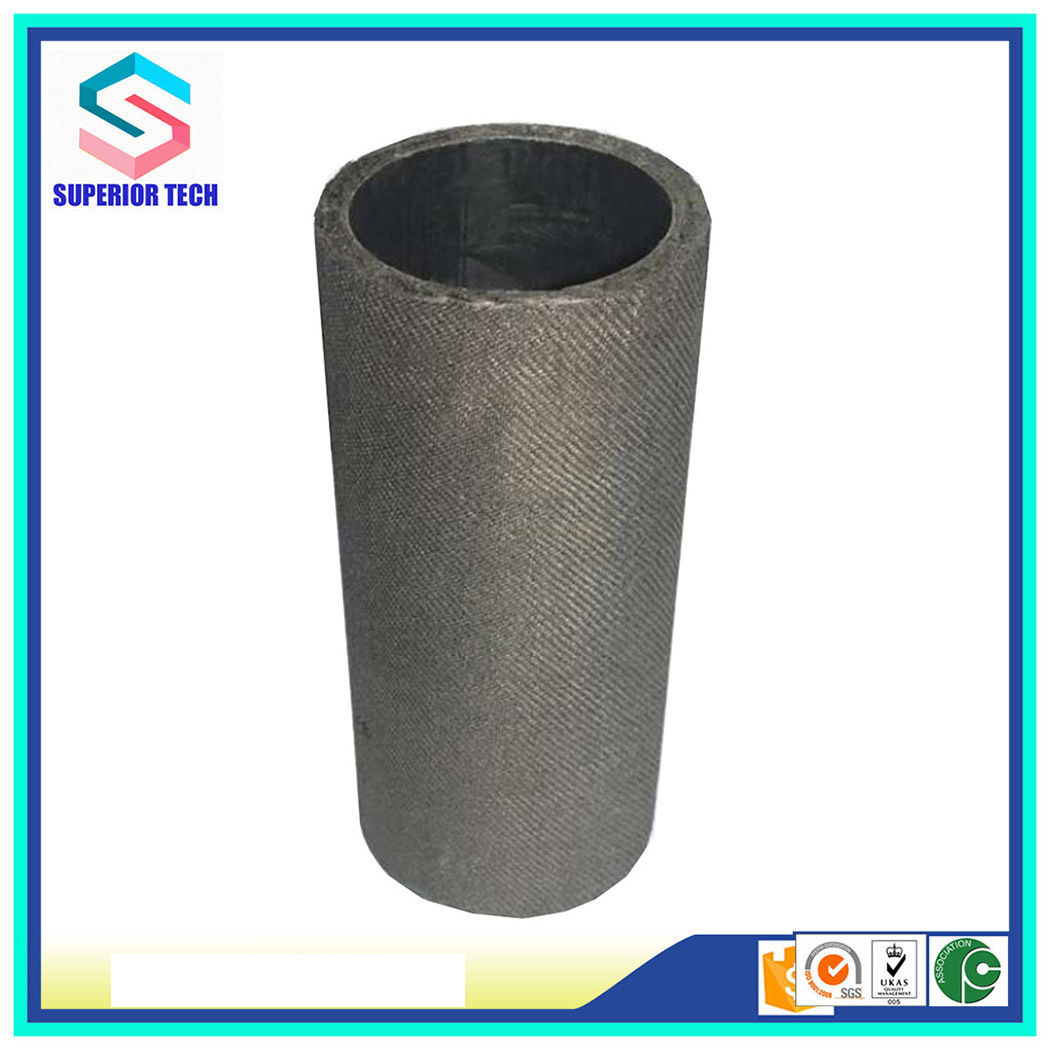

Cylinders are widely used in insulation materials such as monocrystalline silicon, polysilicon, compound semiconductors, optical solders, and other high-temperature crystal growth furnaces.

Advantages:

- Large size flat and shaped components have good integrity

- High mechanical strength

- Good electrical conductivity and heat insulation

- High electrical load force

- Outstanding thermal stability

- High purity, low impurity content

- Excellent shock resistance and corrosion resistance

- Easy to operate and easier to maintain

- Crystal growth furnaces for silicon, etc.

- Sintering furnaces for carbon, ceramics, cemented carbide, etc.

- Brazing furnaces for silver, copper, SUS, nickel, etc.

- Various vacuum evaporation furnaces for aluminum etc.

- Crystal growth furnaces for silicon, etc.

- Sintering furnaces for carbon, ceramics, cemented carbide, etc.

- Brazing furnaces for silver, copper, SUS, nickel, etc.

- Various vacuum evaporation furnaces for aluminum etc.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Fiber Felt for Wafer Growing Furnace Category

Graphite furnace material

Price Range 100.00 - 200.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Other, Graphite

Use : Lining and structural material for electric arc furnaces, induction furnaces, and other hightemperature environments

Style : Other, Industrial

Solid Carbon Fiber

Price Range 100.00 - 500.00 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Material : Other, Solid Carbon Fiber

Use : Industrial Parts, Aerospace, Robotics, Model Making, Structural Reinforcement

Style : Plain

|

GUANGZHOU SUPERIOR TECH CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry