Thermal insulation for vacuum furnace

Product Details:

Thermal insulation for vacuum furnace Price And Quantity

- 50.00 - 100.00 USD ($)

- 10 Piece

- 50 USD ($)

Thermal insulation for vacuum furnace Trade Information

- GUANGZHOU

- Western Union Paypal Telegraphic Transfer (T/T)

- 10000 Piece Per Week

- 7-10 Days

- Yes

- Within a certain price range free samples are available

- Australia South America Eastern Europe Western Europe Middle East Central America Africa Asia North America

- SGS

Product Description

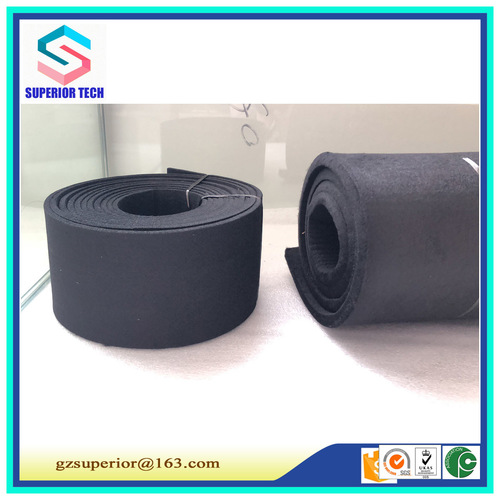

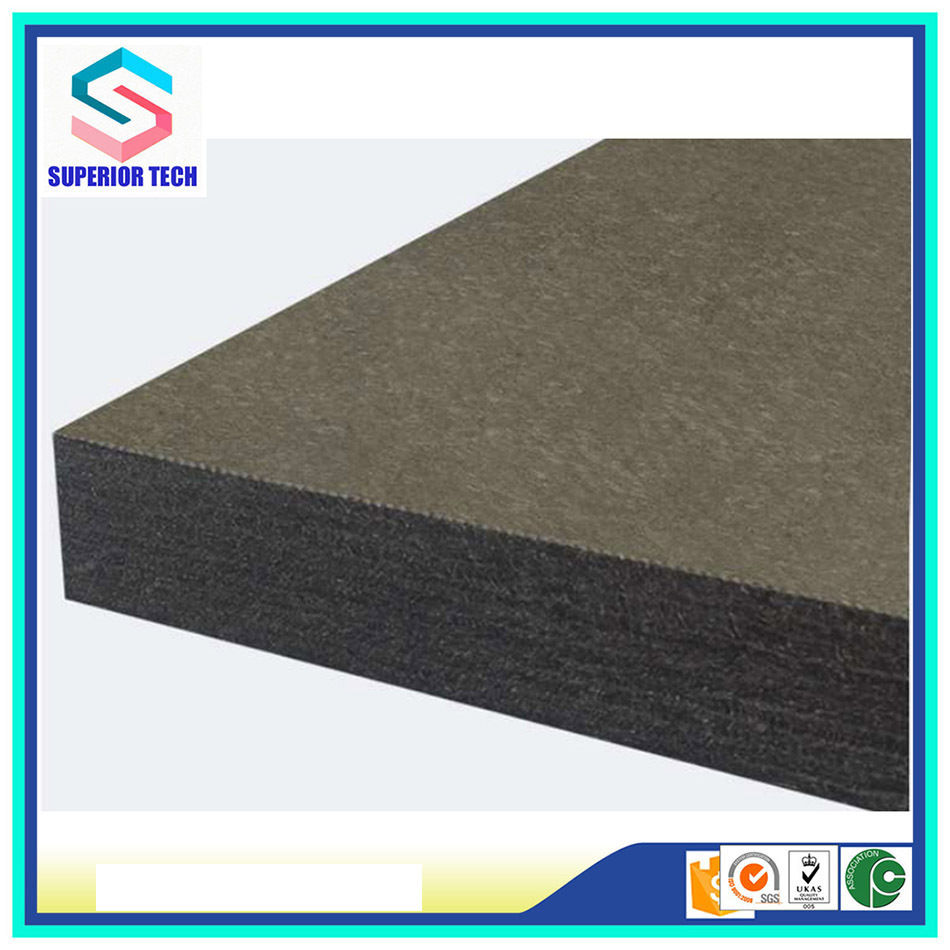

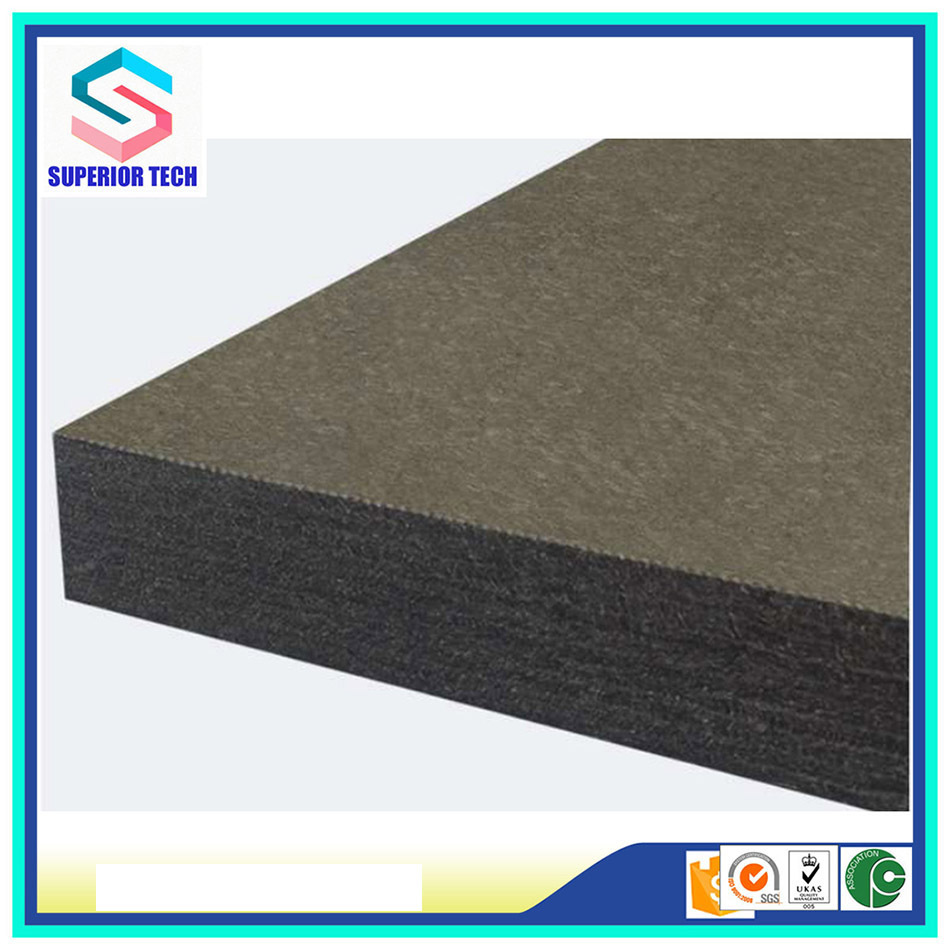

Soft carbon fiber felt advantages:

- Higher uniformity and chemical properties

- Ideal fiber net structure and good felt tensile strength

- Special manufacturing process, graphite soft felt has low thermal conductivity

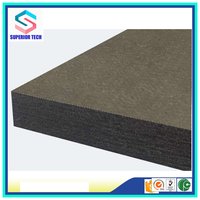

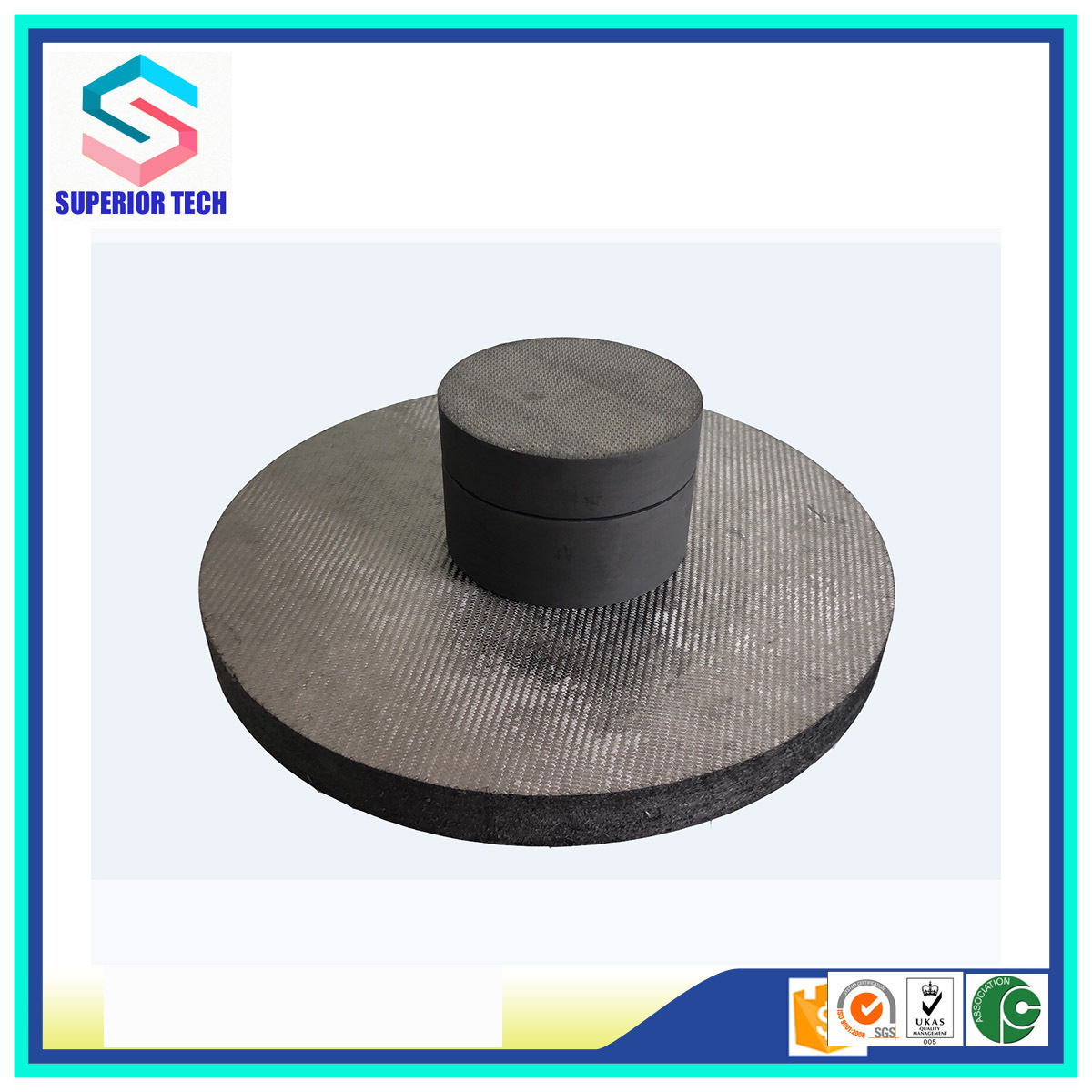

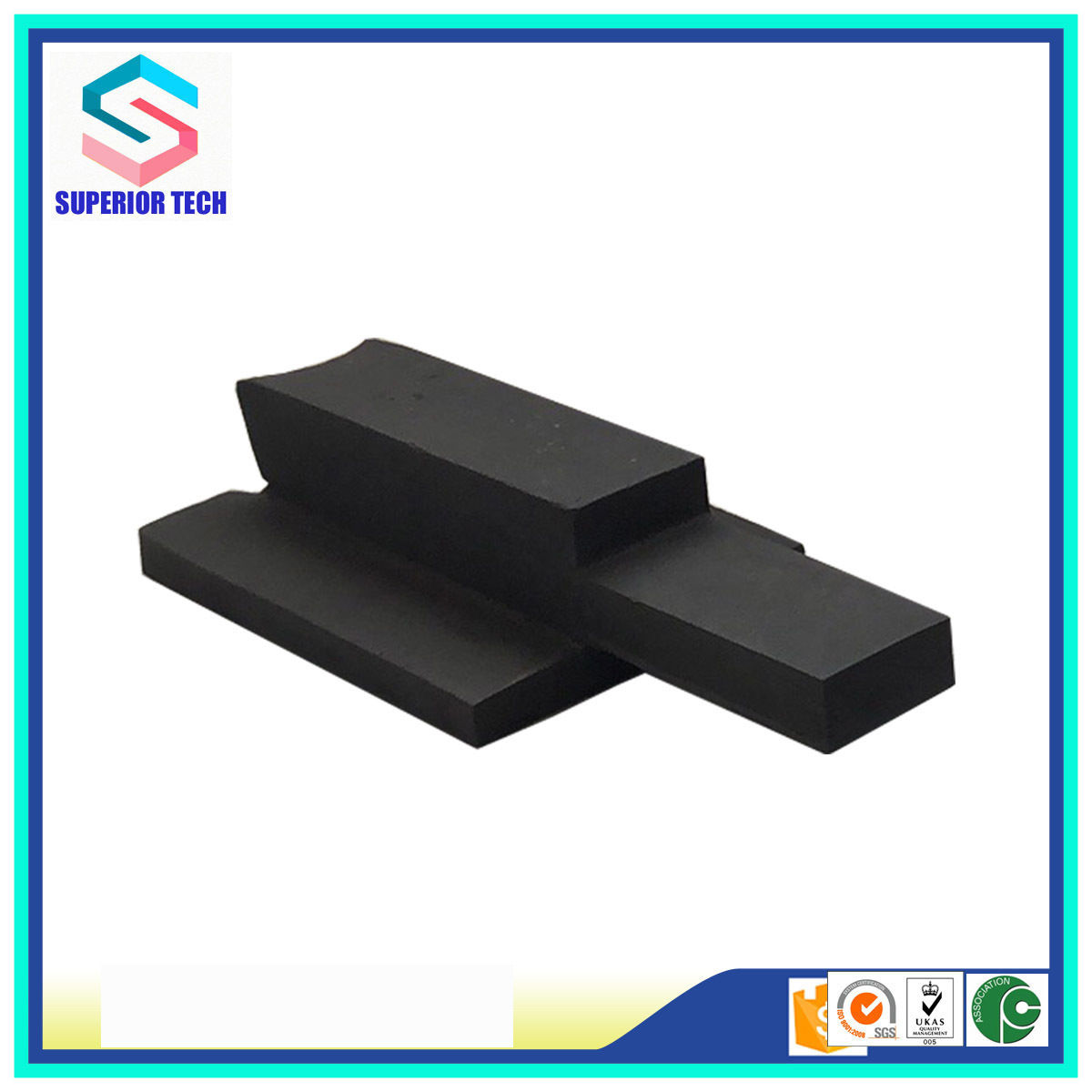

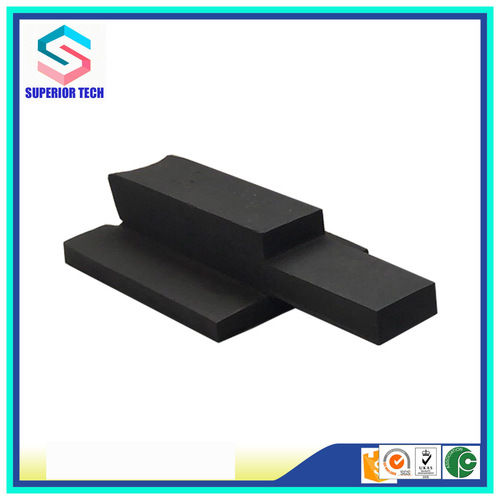

Flat plate carbon fiber felt

The flat plate is mainly used for the temperature vacuum sintering furnace and the inert gas protection furnace, such as single crystal silicon, polycrystalline silicon crystal growth furnace, quartz furnace, vacuum furnace, induction furnace, high frequency furnace and heat balance reaction furnace, heat treatment furnace, hard alloy production, sintering furnaces, welding furnaces, and high pressure furnaces.

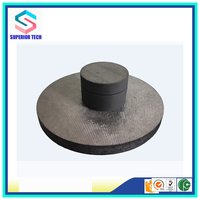

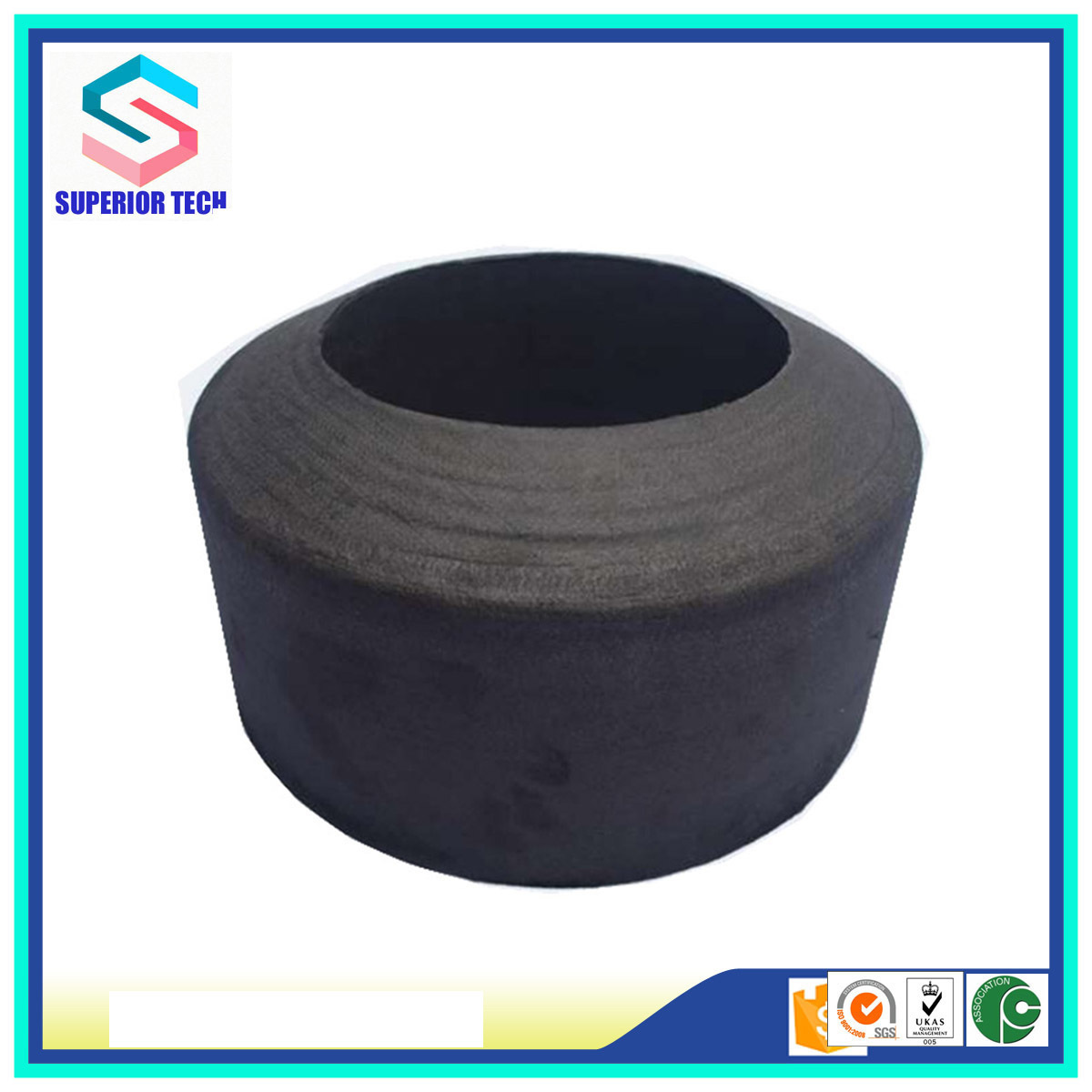

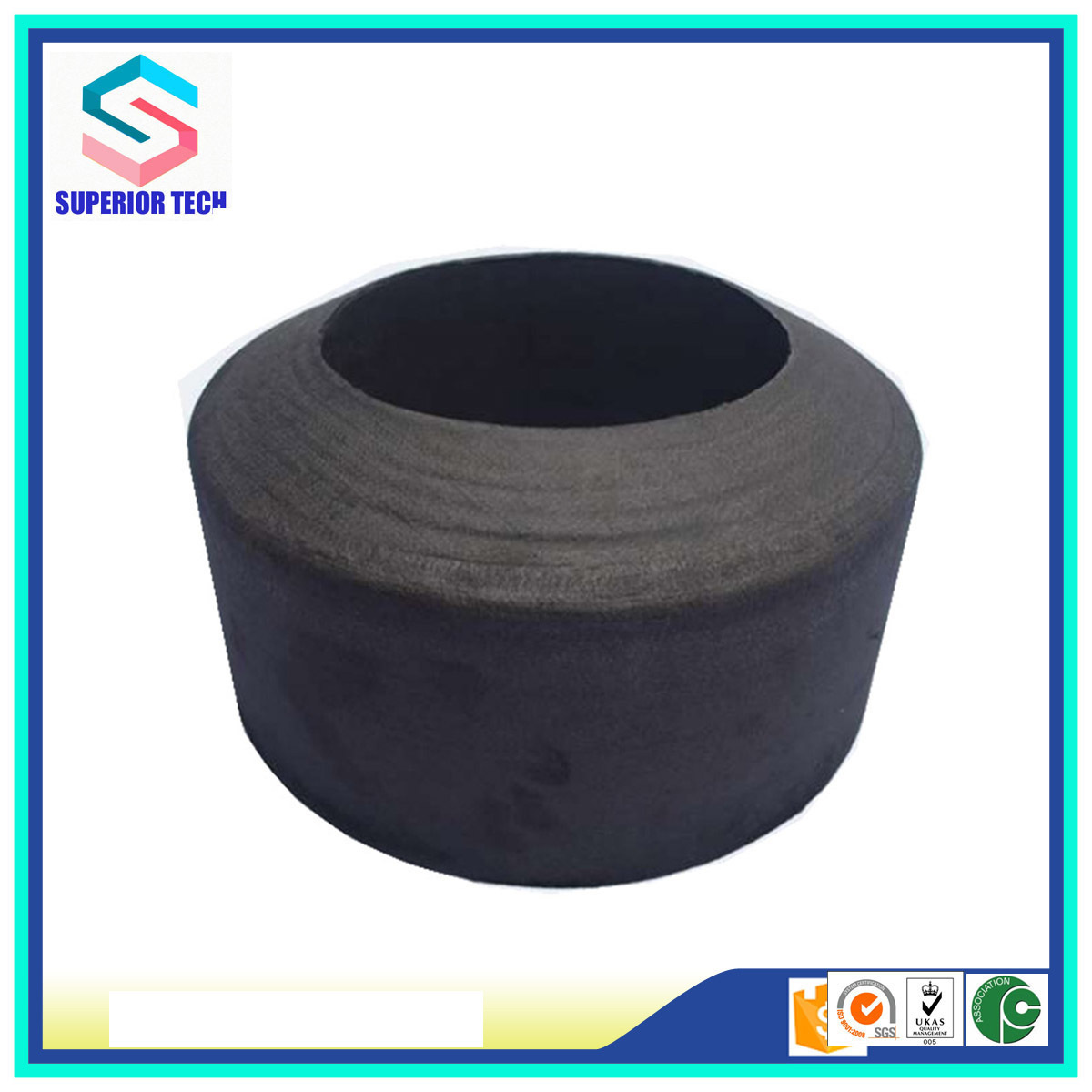

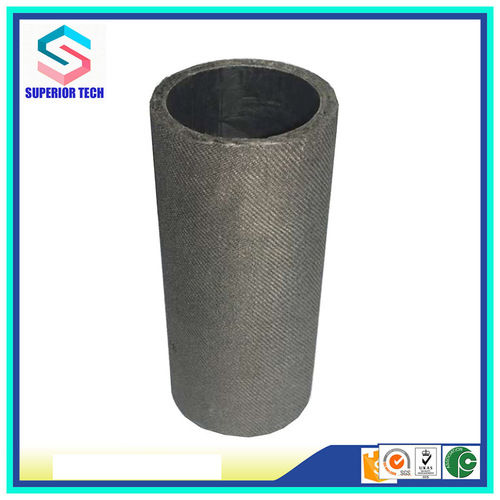

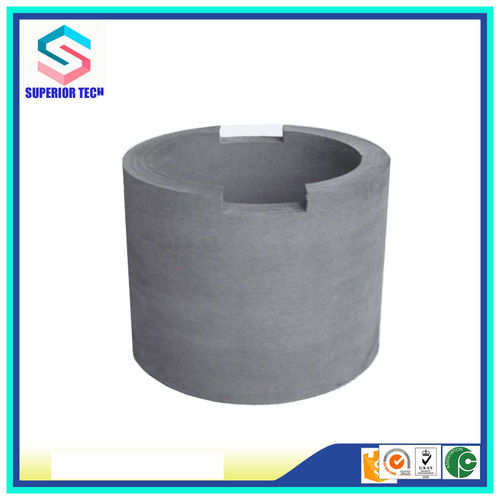

Cylinder construction Carbon thermal insulation

As a thermal insulation material for crystal growth furnaces, cylinders are widely used in the production of monocrystalline silicon, polycrystalline silicon, compound semiconductors and optical fibers.

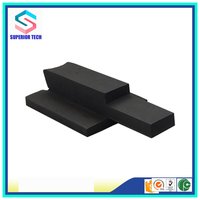

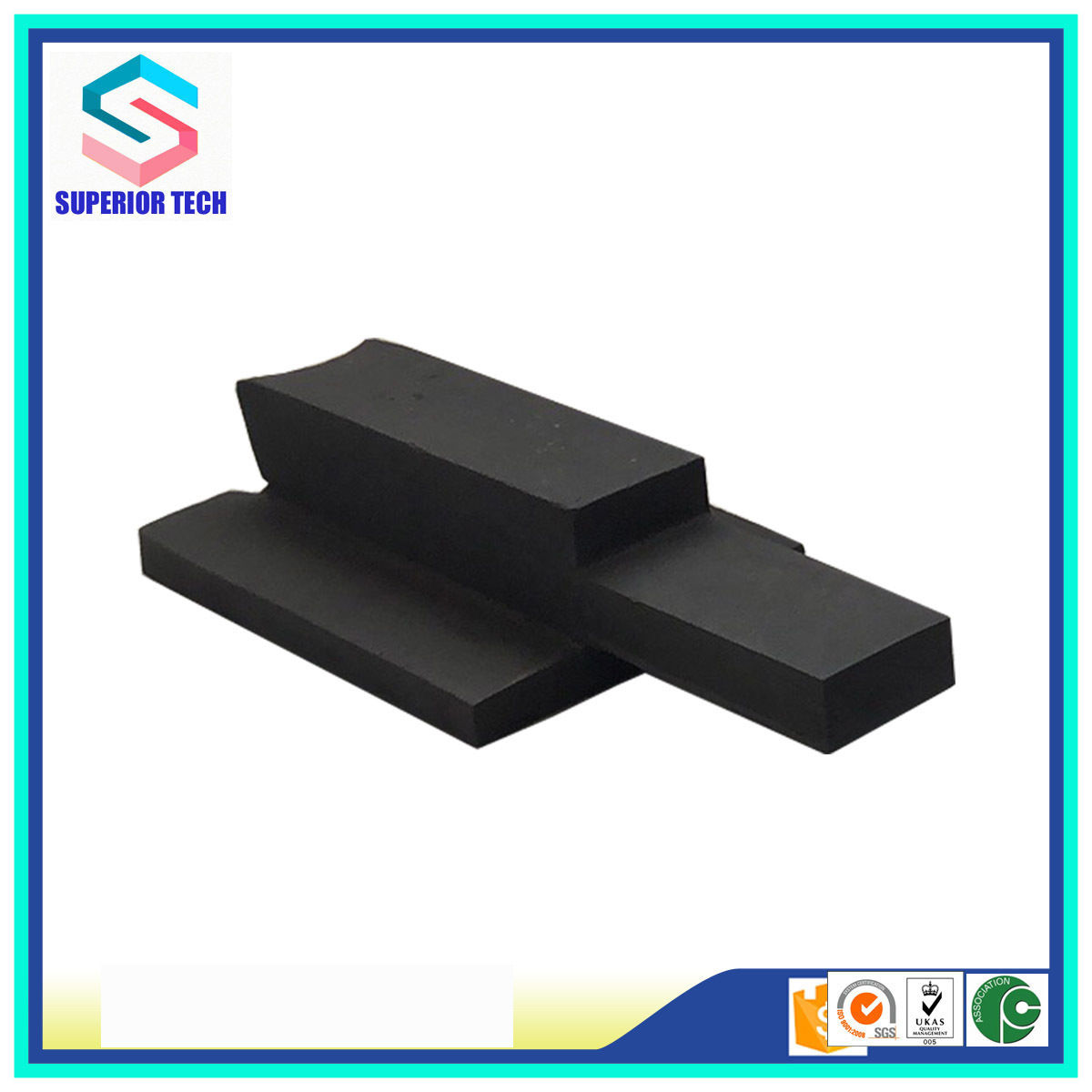

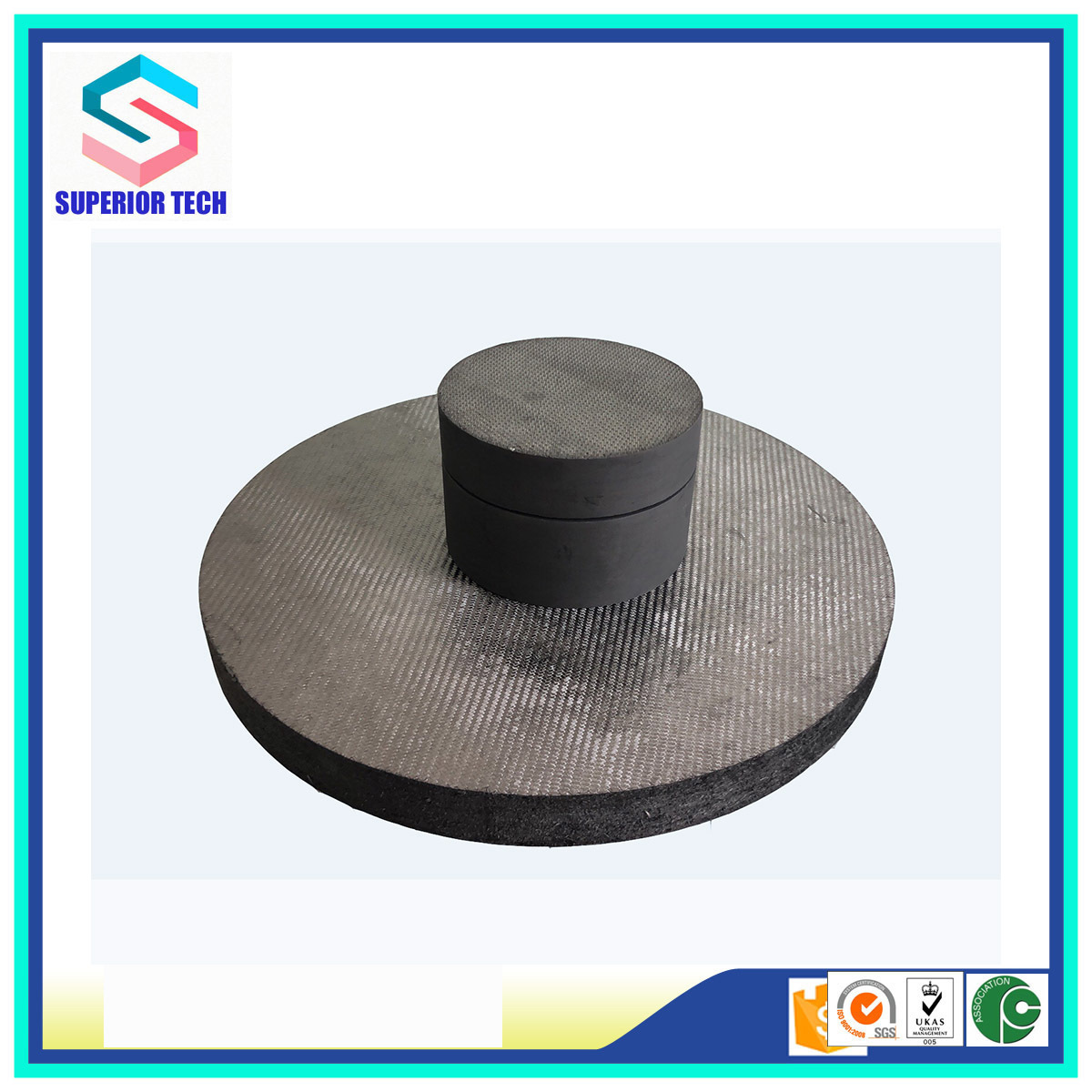

Carbon-carbon composite structural materials are particularly suitable for use in high temperature furnaces or chemical processing technology environments in an inert atmosphere or vacuum environment.

Adopting advanced 3D structural panels, through high-quality processes and reliable diamond tooling equipment to ensure its structural strength in the working environment.

Vulcan's fiber composite thermal field materials ensure the purity of the material products through the purchase of high-quality raw materials and the optimization of high-tech processes. Through the long-term 2400-degree graphitization process, most impurities have been evaporated to ensure safe production.

| Performance | Standard | Purified | |

| Material | PAN(polyarylonitrile) | PAN(polyarylonitrile) | |

| Bulk density g/cm3 | 0.16-0.18 | 0.16 | |

| Carbon content wt% | 99.9 | 99.99 | |

| Processing temperature | 2000 | 2400 | |

| Compressive strength MPa | Surface | 0.71 | 0.7 |

| Side face | 0.4 | 0.39 | |

| Bend strength MPa | Surface | 3.52 | 3.45 |

| Side face | 1.84 | 1.82 | |

| Electrical resistivity m | Surface | 1.45 x 10-3 | 1.39 x 10-3 |

| Side face | 18.2 x 10-3 | 16.5 x 10-3 | |

| Thermal conductivity W/(m K) | 1500 | 0.28 | 0.25 |

| Thermal expansion 10-6 / | 1500 | 3.4 | 3.2 |

| Ash content PPM | 200 | 50 | |

| working environment

| Air | 400 | 400 |

| Vacuum | 2200 | 2200 | |

| 3200 | Work environment | 3200 | |

| Plate size(mm) | Max: L2500 x W2500 x H200 | Max : L2500 x W2500 x H200 | |

| Cylinder size(mm) | Max:OD1500 x T200 x H2500 | Max:OD1500 x T200 x H2500 | |

Other Products in 'Carbon Fiber Felt for Wafer Growing Furnace' category

|

GUANGZHOU SUPERIOR TECH CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry